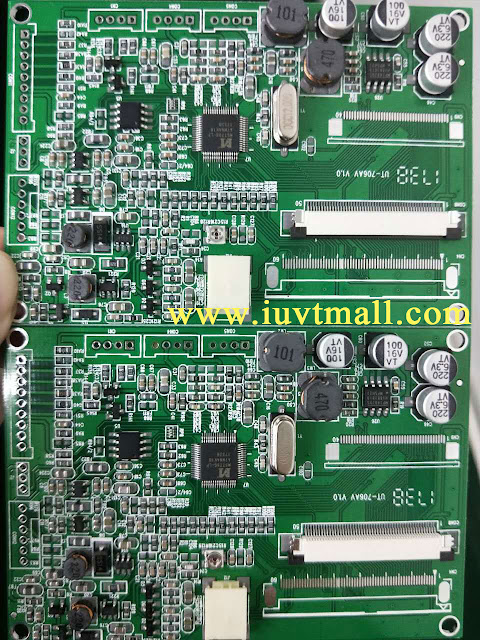

9. The design of PCB (multiple layer board)--Basic requirement of designing multiple layer PCB VOL1

6. Basic requirement of designing multiple layer PCB

Juvtmall ( a company supply PCB Prototyping, PCBA service and sell kinds of components, modules and so on)

Determine out shape, size, layers.

Any plate, there are problems with other structural parts, so the shape and size of the printing plate must be based on the product machine structure.

However, in terms of production process, it should be as simple as possible, generally for the long width ratio not too wide of the rectangle, to facilitate assembly, improve production efficiency, lower labor cost.

The number of layers must be based on the circuit performance, the size of the plate and the intensity of the line.

In the case of PCB multilayer, the application of four layers and six laminates is the most widely used, with four layers as an example, which is two conductor layers (surface and welding surface), a power supply layer and a layer.

The layers of the multilayer should be symmetrical and preferably even the copper layer, which is four, six, eight.

Due to the asymmetric layer pressure, the surface of the plate is prone to warping, especially for the surface mounted multi-layer board, more should be noticed.

Position and orientation of components

The position and orientation of the components should first be considered in the principle of the circuit to meet the direction of the circuit.

The reasonable arrangement of the plate will directly affect the performance of the printing plate, especially the high frequency analog circuit, which will be more strict in the position and placement of the device.

Reasonable placement of components, in a sense, has already predicted the success of the printing plate design.

So, in the layout of the PCB layout, determine the overall layout, should be a detailed analysis was carried out on the circuit principle, first to determine the specific components (such as large-scale IC, high-power tube, signal source, etc.) of the position, and then arrange other components, to avoid possible interference factors.

On the other hand, the overall structure of the printing plate should be considered to avoid the irregularity and disorganization of components.

This not only affects the printing plate's aesthetics, but also brings a lot of inconvenience to the assembly and maintenance work.

The other blog

The other blog

评论

发表评论